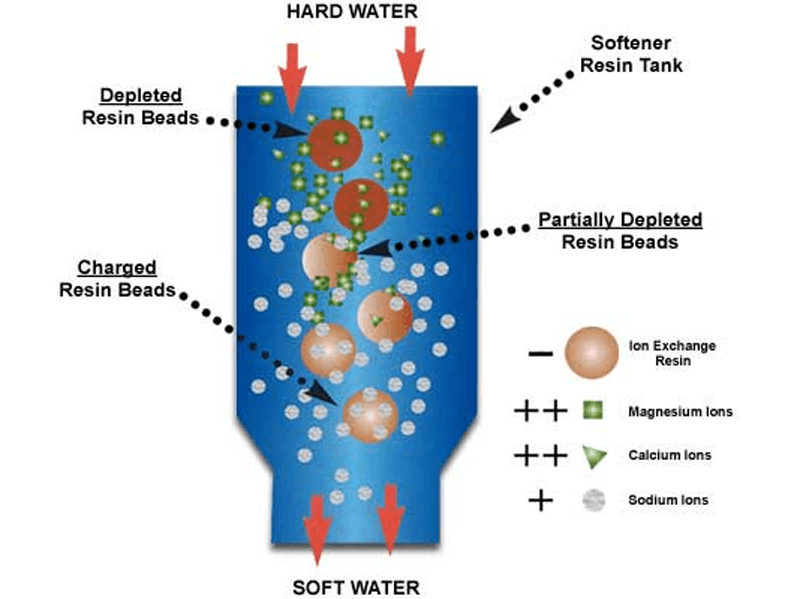

A water softener is used to reduce the hardness of water and meet the requirements of operating conditions. Water hardness is composed of cations calcium (Ca) and magnesium (Mg) ions. When hard water passes through the cation resin layer of the softening water device, calcium and magnesium ions in the water are absorbed by the resin and sodium ions are simultaneously released. The water flowing out of the exchanger is then softened water with the hardness ions removed. When the resin that absorbs calcium and magnesium ions reaches a certain degree, it loses exchange capacity. At this point, the water softener automatically executes the regeneration of failed resin according to the predetermined procedure. By using a higher concentration of sodium chloride solution to pass through the resin, the failed resin is restored to sodium-type resin.

The main components of the WZHDN water softening device are:

1. Automatic control valve: The valve body is made of high-strength lightweight corrosion-resistant engineering plastic and lead-free brass.

2. Corrosion-resistant tank: The tank body is made of fiberglass (carbon steel or stainless steel-lined plastic tank body can also be used), which is corrosion-resistant, pressure-resistant, and has a long service life.

3. Inlet and outlet water distribution device: Mother branching water distribution is adopted, and the effective exchange capacity of the resin is fully utilized, with uniform distribution of inlet and outlet water.

4. High-performance softening resin: Strong acid cationic exchange resin is selected, which has a low breakage rate, uniform particle size, and improves ion exchange rate.

The working process of the WZHDN water softening device is:

First, run the water production, and the untreated water passes through the resin layer to undergo an exchange reaction. The outlet water is qualified softened water. Then, backwash the water from the lower part of the resin layer to loosen the resin and remove fine debris. The next step is brine regeneration: Use a higher concentration of brine (NaCl) to flow through the resin to restore the failed resin to sodium-type resin. Then, rinse according to the water supply process to flush away excess salt solution and calcium and magnesium ions exchanged during regeneration. Then, fill the salt box with water to dissolve regenerated salt for the next regeneration.

Activate the automatic cleaning and regeneration section time control and flow control. Time control is to set the regeneration cycle according to the hourly output and periodic water production. It is generally suitable for occasions with relatively stable water consumption. Flow control is to start the regeneration program according to the periodic water production. When the total production water volume reaches the set periodic water production, the controller starts the regeneration program for automatic regeneration. The regeneration of the device is not related to the running time and is generally suitable for occasions with unstable water consumption and continuous use.

Post time: Aug-01-2023